English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

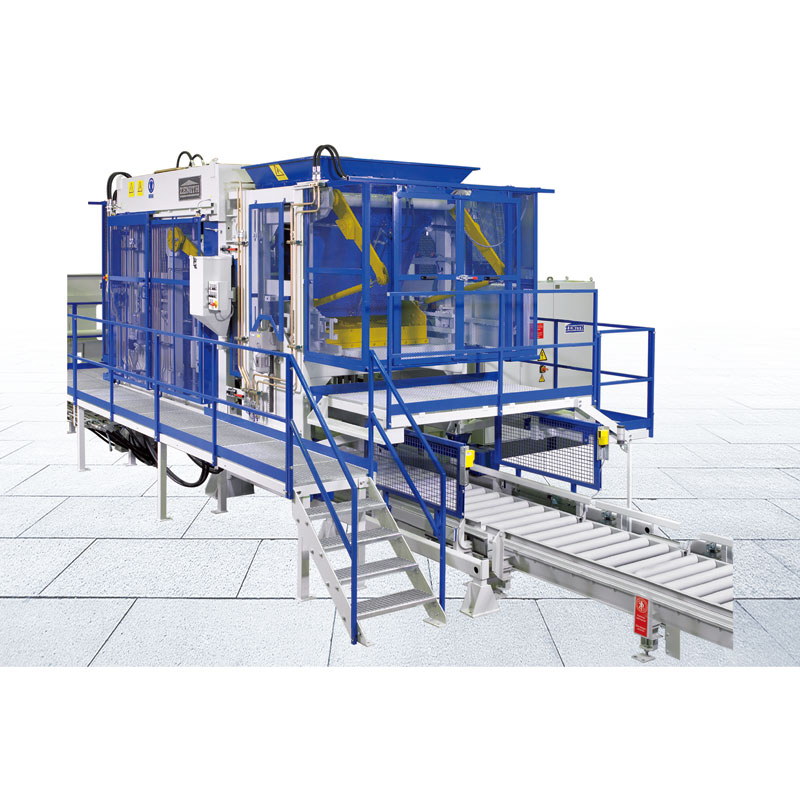

I-Zenith 913 Brick Laying Machine

Thumela Uphenyo

Izici Zobuchwepheshe Eziyinhloko

I-1) Imodi yokulawula ngesandla: Ukusebenza kwemishini kungalawulwa ngemodi yezandla ngokusebenzisa i-valve yokulawula isiqondiso. I-valve yokulawula isiqondiso iqukethe amamojula amabili: induku yokulawula isiqondiso kanye nenkinobho yokufundisa edidiyelwe, enokulawula okunembile, ukusebenza okulula kanye nokuhamba okuqinile.

2) Imodi ye-automation egcwele: Umshini wokuvimba ubuye ufakwe isilawuli esizenzakalelayo esisetshenziselwa ngokukhethekile umshini wokwenza ibhulokhi ephathwayo. Ama-opharetha angasebenzisa okokusebenza kalula ngesikrini sokubonisa esinombala obonakalayo ukuze bathole ukukhiqizwa okuzenzakalelayo.

3)Ukulawula ukuguqulwa kwemvamisa: Injini yalesi sixhobo isebenzisa isistimu yokulawula ukuguqulwa kwemvamisa, equkethe ukusetshenziswa kwamandla okuphansi nokusebenza okuzinzile. Lolu hlelo lokulawula lunamandla okulawula ukucindezela kwe-prec. Iyunithi yokushayela kagesi elawulwa ukuguqulwa kwemvamisa ingaqinisekisa ukuhamba ngokushesha nangokushelela kwezinto okokusebenza, kukhuphule ukusebenza kahle kanye nokuncipha kwezindleko.

4)Ukushintsha isikhunta esisheshayo: Umshini usetha uchungechunge lwemibandela ye-coefficient yesikhunta ngokusebenzisa lolu hlelo. Lolu hlelo lokubuyisela isikhunta lunemisebenzi yokukhiya okusheshayo kwemishini, ukubuyisela ngokushesha isikhunta ikhanda le-tamper, ukuphakama okulawulwa nge-elekthronikhi kwedivayisi yokondla, njll., okuqinisekisa ukuthi isikhunta esihlukahlukene singashintshwa ngesivinini esisheshayo.

5)Ukuhlakazwa ngokushesha kwenetha elivikelayo: Isiphethu se-telescopic sifakwe kunetha elivikelayo ngokufakwa okusheshayo nokuqaqa. Kulula ukuhlanza nokugcina isikhunta. Imodi yokukhiya eqinile futhi elula ingaqinisekisa ukuphepha okuphezulu komqhubi ngenkathi inikeza lula.

Idatha Yezobuchwepheshe

| Izici | |

| Ivolumu ye-Hopper | 1,000L |

| Ukuphakama okuphezulu kokuphakelayo kwesilayishi | 2,005L |

| Ubude bokwakha obukhulu | 1,240mm |

| Max.forming ububanzi | 1,130mm |

| Ubude bomkhiqizo obuncane | 175 mm |

| Ubukhulu. ukuphakama komkhiqizo | 330 mm |

| Isisindo | |

| Kubandakanya isikhunta kanye ne-vibration motor | 5T |

| Usayizi | |

| Ubude obuphelele | 2,850mm |

| Ubude obuphelele | 3,000mm |

| Ububanzi obuphelele | 2,337mm |

| Isistimu yokudlidliza | |

| Amandla amakhulu ajabulisayo wetafula lokudlidliza | 48KN |

| Amandla aphezulu ajabulisayo wokudlidliza okuphezulu | 20KN |

| Ukusetshenziswa kwamandla | |

| Ngezinombolo eziphezulu ze-vibration motor | 16KW |

I-Zenith 913 Isakhiwo Somshini

Amandla Okukhiqiza

| Vimba Uhlobo | Ubukhulu(mm) | Izithombe | Ubuningi/Umjikelezo | Isikhathi Somjikelezo | Amandla Okukhiqiza(Ngama-8hs) |

| I-Hollow Block | 400*200*200 |

|

12 | 35s | 9,792pcs |

| 400*150*200 | 16 | 35s | 13,165pcs | ||

| 520*160*200 | 12 | 35s | 9,792pcs | ||

| I-Soild Block | 225*112.5*80 |

|

12 | 35s | 9,792pcs |