English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

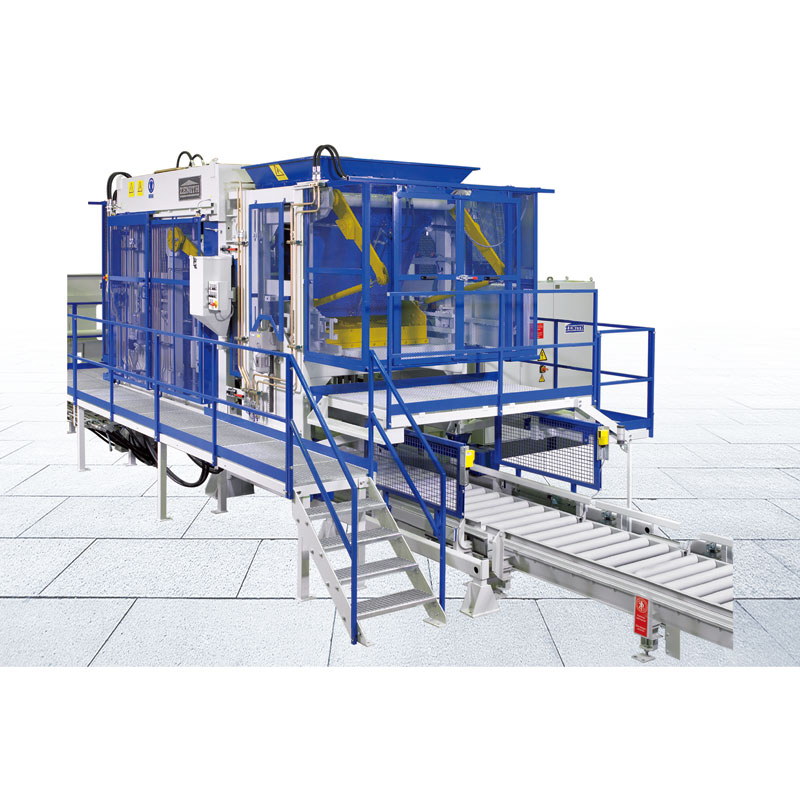

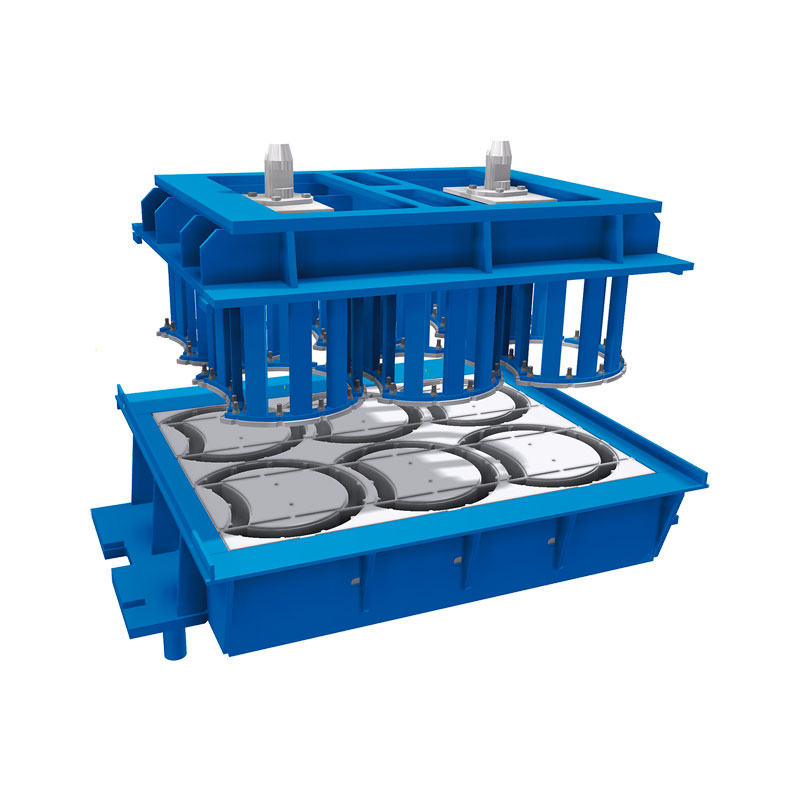

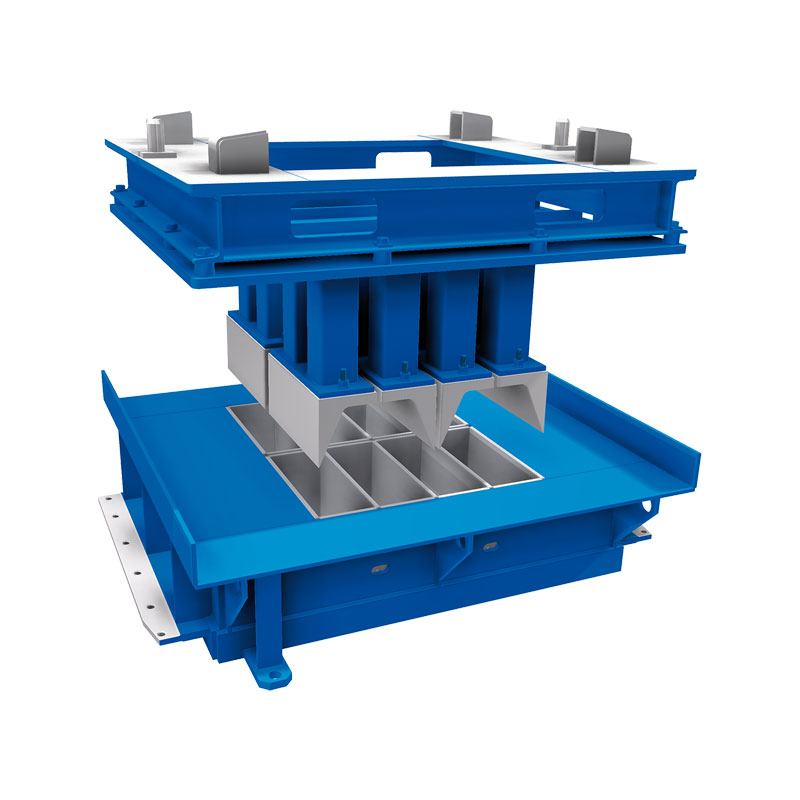

I-Hollow Block Mold

Thumela Uphenyo

Ungaqiniseka ukuthi uthenga i-Hollow Block Mold eyenziwe ngokwezifiso kithi. Izibungu ze-block ezingenalutho zenziwe ngensimbi engagqoki yekhwalithi ephezulu. Ngenqubo yokusika ucingo, igebe phakathi kwezinhlangothi ezingenhla neziphansi zesikhunta linengqondo, imvume engu-0.8-1mm, okwenza isikhunta siqine futhi siqine. Inqubo ehlanganisiwe yokwelapha ukushisa yenza isikhunta singagugi futhi siqine. Ngokwezidingo zamakhasimende ahlukene, ingahlinzeka ngemininingwane ehlukahlukene kanye nemiklamo. Isikhunta samukela umklamo oguquguqukayo, ngokwezidingo zamakhasimende, umgogodla wesikhunta, ipuleti lokucindezela lingashintshwa ngokukhululekile, futhi sihlinzeka nge-welding, i-modular thread locking design kanye nokukhiqiza.

Okwesikhunta se-superstructure emiklameni ehlukahlukene, i-ZENITH iwuphawu lokwethembeka nokwehlukahlukana komkhiqizo. Kulapha lapho amandla ethu namakhono kukho kokubili ubuciko kanye nobuchwepheshe besimanje be-CNC bunomthelela omuhle kakhulu enanini lezibunjwa zethu.

I-Hollow block molds Design:

A) UMDIZINI WOKUKHULA USHISHISELWE

Ikhwalithi ephezulu yokugqoka insimbi engazweli

Ukususwa kwezicathulo 0,5-0,8 mm

Ukubamba ukujiya kwewebhu kugoqiwe ngakho kuyashintsha

Izicathulo ezishintshayo ezinamabhodwe angaphakathi ekhanda le-tamper

Umklamo oqinile futhi ofakazelwe

Ukuxhashazwa kahle kwesikhunta

Idizayini yeshidi lokuhoxisa ozikhethelayo

Ukukhiqiza okungabizi kakhulu

Umklamo wendabuko nofakazelwe

B) UKWENZIWA KWESIKHUNGO ESILUKWE

Idizayini eguquguqukayo yesikhunta Imvume yezicathulo 0,5-0,8 mm

Ukubamba ukujiya kwewebhu namasetha akrufulwe

Izicathulo ezishintshayo ezinamabhodwe angaphakathi ekhanda le-tamper

Ukwakhiwa okungenakucindezeleka

Idizayini yeshidi lokuhoxisa ozikhethelayo

izingxenye zangaphakathi zingenzeka ngenguqulo ye-nitrate(62-68 HRC).

Ngokusekelwe ezidingweni zamakhasimende, singase futhi sinikeze inhlanganisela ye-welding kanye ne-modular threaded connection design.