English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

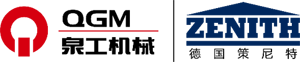

Paver Mold

Thumela Uphenyo

Njengomkhiqizi ochwepheshe, singathanda ukukunikeza i-Paver Mold. Isikhunta se-QGM paver sithatha insimbi ephansi ye-carbon alloy high amandla e-carburizing futhi sihlanganisa ubuchwepheshe bokusika izintambo ezinembilehigh-precision CNC processing technolbgy kanye nobuchwepheshe bokuskena be-3D ukuze kunikeze abathengi ukwenza ngokwezifiso isikhunta. Lobu buchwepheshe bungaklama okuyize kwamakhonsathi kanye nokwakheka kwejiyomethri.Ukucaciswa kwayo okungu-0.3-0.4mm, okunamakhona aqondile aqondile kanye namakhona:izindonga ezisemaceleni ezinobude. Amapavu akhiqizwe yi-QGM abunjwa kalula, anemba kakhulu, awekho ama-burrs azungezile. Isikhunta singabona idizayini ye-digital freesurface kanye nomklamo wokushintshisana wamapuleti okucindezela.

Ukuze kuqinisekiswe ukuqina kwesikhunta, isikhunta se-QGM paver sithatha ukwelashwa kwe-carbunizing., amafreyimu esikhunta namapuleti okucindezela aqiniswa 60-63HRC, futhi ukujula kokuqina kwe-mirnimuim kungu-1.2m.Ngokwezicelo zamakhasimende, isikhunta singaklanywa futhi eyenziwe nge-welding noma ukukhiya intambo ye-modular.

Sinikeza i-Paver Molds yekhwalithi ephezulu yazo zonke izinhlobo zemishini nokufakwa kwamathuluzi ekwakhiweni okulandelayo:

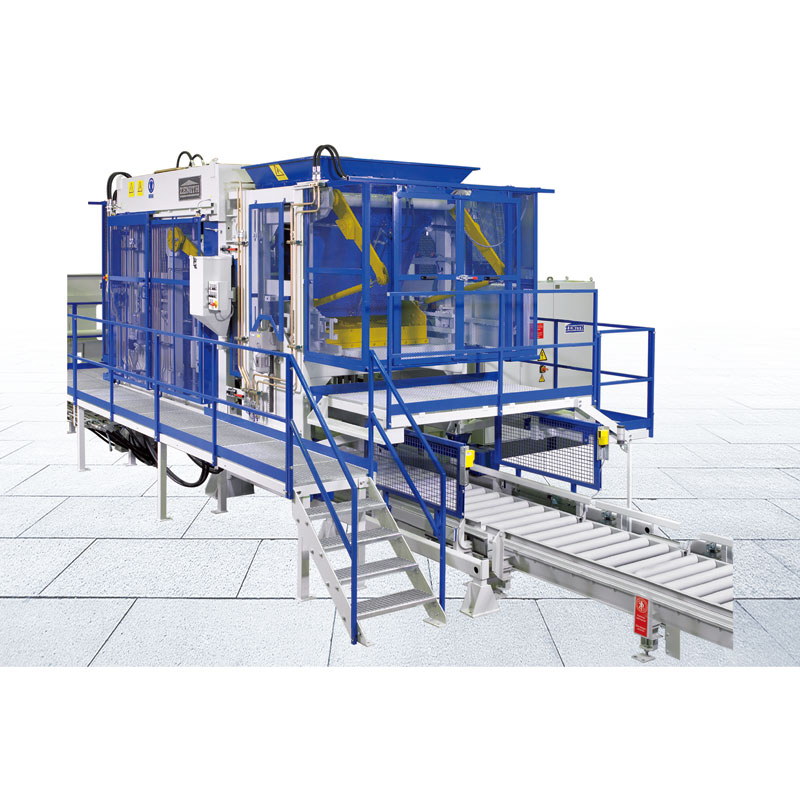

A)KWENZAKALA IMLILABI

Ubukhulu bewebhu obuncane bungenzeka

Ukuxhashazwa kahle kwesikhunta

Imvume yesicathulo esincike emshinini engu-0,2-0,5 mm

Izindonga eziseceleni eziphikisayo zingenzeka

Awekho ama-grooves okubambile adingekayo

Idizayini evamile yemishini yokukhiqiza izendlalelo eziningi

Idizayini yeshidi lokuhoxisa ozikhethelayo

Ngomklamo wedijithali wedijithali obonakalayo obonakalayo

Umklamo wezicathulo zezitembu ezishisayo uyasebenza

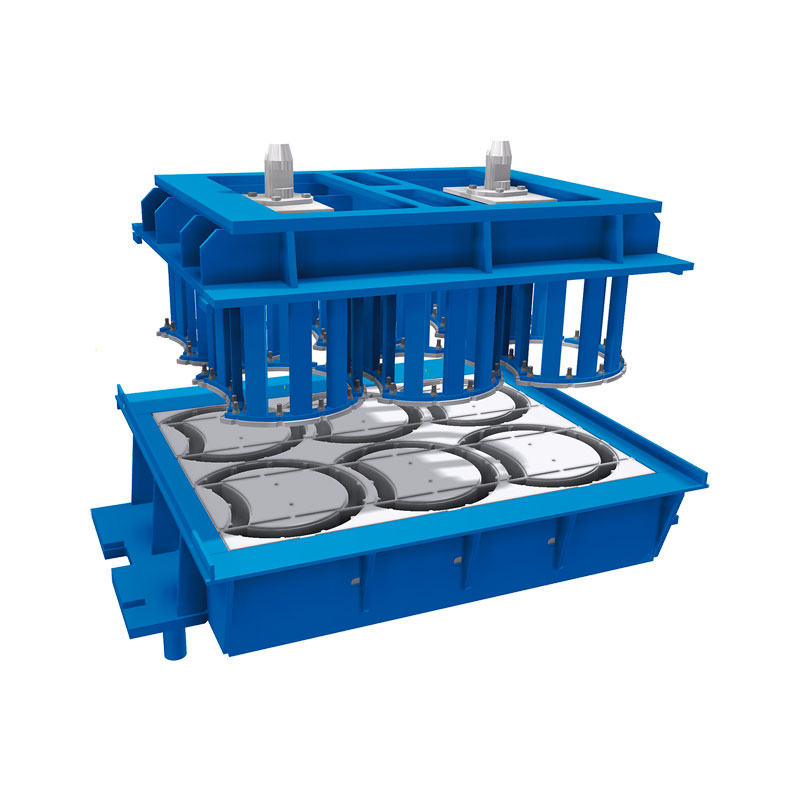

B)UMSEBENZI WOKUQINISEKISA

Isebenza kuwo wonke ama-contours namajiyometri

Ukubekezelela ebhokisini lesikhunta ngezansi +/-0.3 mm

Imvume yesicathulo esincike emshinini engu-0,2-0,5 mm

Izindonga eziqondile eziqondile, ezinama-engeli futhi ezibushelelezi

Ukudiliza kalula

Ukunemba okuphezulu kokulingana

Izibambisikhala kuzo zonke imiklamo engenzeka

Idizayini yeshidi lokuhoxisa ozikhethelayo

Ngomklamo wedijithali wedijithali obonakalayo obonakalayo

Umklamo wezicathulo zezitembu ezishisayo uyasebenza

Ukuvikela ukugqoka kuzo zonke isikhunta se-pavement kanje:

A)I-CARBURIZING(62-68 HRC)

Ibhokisi lesikhunta nezicathulo zesitembu ziqinisiwe (62-68 HRC)

Ubulukhuni bokungena min. 1,2 mm

B)I-NITRATING (62-68 HRC)

Ibhokisi lokukhunta nezicathulo zesitembu ezifakwe i-nitrate (62-68 HRC)

Ubulukhuni bokungena min. 0,4 mm

Akukho ukucindezeleka kwangaphakathi uma kuqhathaniswa nezibunjwa eziphathwa nge-carburizing

Inconyelwe ukujiya okuncane kwewebhu

Ukunemba okuphezulu kwe-contour phezu kwesikhunta esiphathwe nge-carburizing

Ngokulandela izimfuneko ezivela kumakhasimende, isikhunta sethu singaklanywa futhi sikhiqizwe ngezindlela zokukhiya intambo yesikulufu esishisela noma semodular.